Originally Posted by

Ascinder

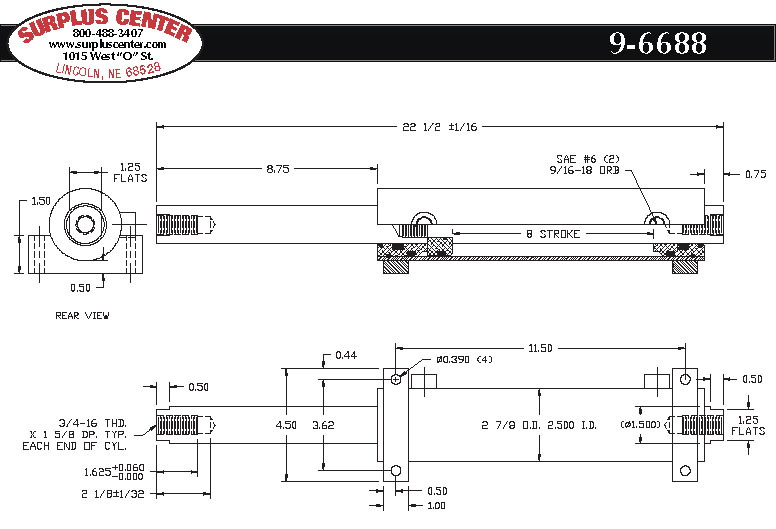

No breakthroughs yet. I have been trying to pin down what I want to use for my Hydro steering and also been trying to find a good set of full hydraulic capable highsteer arms that have adjustable kingpin preload centercaps. What do you think about this idea? What I want to do is get the double ended arms like these:

But instead of just getting one short and one double ended arm for crossover steering, I would get two double arms so that I could run the ram behind the differential, and a high mounted tierod across the front. The way I'm envisioning it is that the steering would be somewhat similar to a parallelogram, but one that would pivot off of the kingpin caps not the bases. Does that make sense? The only thing I'm running into is that I really don't like this picture:

It looks like the hydro side of the parallelogram would not be a straight line and may cause things to act funny. I think it might just be in my head though. Common sense dictates that if I have two(four) points that are equidistant from their respective pivot points, that all the angles will stay the same-parallelogram style. In other words, as long as the distance(and angles) between the two forward steering arms stays the same, the rears have to match too, so even if the hydro steer diagrams look funky, they should still work right anyways with a tierod added across the backs. Maybe I'm overthinking/analyzing this stuff though.......

I have thought about this after you brought up the potential issues and I think you are right to concern yourself. I'm not real sure of the severity though.

The fault I see in the design is different than what you may have been concerned with though. I see the major issue as this... the linking rod that acts as a bridge between the two steering arms never adjusts in length while the rods at the ends of the plungers have to swivel to compensate for the throw of the steering arms. That swiveling motion would cause a subtle variation in length between the steering arms that would apply deflective pressure to the linking rod. I just created the basic concept with single lines in AutoCAD and in my sketch I noticed a difference of -5/16" in distance applied to the linking rod from the point of center (no steer) to 40 degrees of steer (using 10" arms from kingpin to arm end - so 20" total arm length).

We could get much more accurate with what you are dealing with if you knew the length of the steering arms, the kingpin separation, the angle of max steering throw, the distance of separation between the ends of the plungers, and the location off axle center line to the center of the ram. I hope you know what I mean... The "more desirable" method in your illustration would lessen the degree of severity of the "most desirable" method because of the equal angle of the rods at the ends of the plungers during full lock and seemingly during the whole of the steering motion but there would most likely still be a variation in length.

Remember when I asked you, "Why do we do this to ourselves?"?  As always, I may or may not be correct!

As always, I may or may not be correct!

Last edited by ZEUS : 03/11/2010 at 01:13 PM

Sent from my "two hands on a keyboard"

Reply With Quote

Reply With Quote

As always, I may or may not be correct!

As always, I may or may not be correct!

I was thinking more along the lines of

I was thinking more along the lines of