Hi, I recently bought a VX. It's not insured yet so I don't drive it yet but I drove it for 1300 miles from where I bought it. It's a 1999 with 54K miles. The last time I noticed that if I shift between Reverse - Neutral - Drive - I can hear what sounds to me like a hit in the transmission. Especially going from Neutral to Reverse or from Neutral to Drive. You swith it and then you hear - Bang! - it switched. It just sounds like it hits something way too harder than it should.

It was probably the same way when I bought it, I just probably didn't notice it at first.

Also today I looked under the car and I found some oil on the floor in the area of somewhere between the driver and a passenger front seats. It's red in color so I assume it's dextron. I looked where it was coming from and it looks to me like it's coming from a (I only assume that's what it is) transmission cover - there was a drop hanging on the drain plug and another drop further to the back and all the cover from around the drain plus to the back is wet. When looking more at this I found another bolt higher and to the back from the drain plug and everything is wet around it too. It doesn't look like it's leaking from the gasket so it may be just a copper washer that needs to be replaced on both of those bolts.

Now my questions. Is the first problem with bang sound normal sound or not. If it's not - can it be caused by low level of transmission fluid?

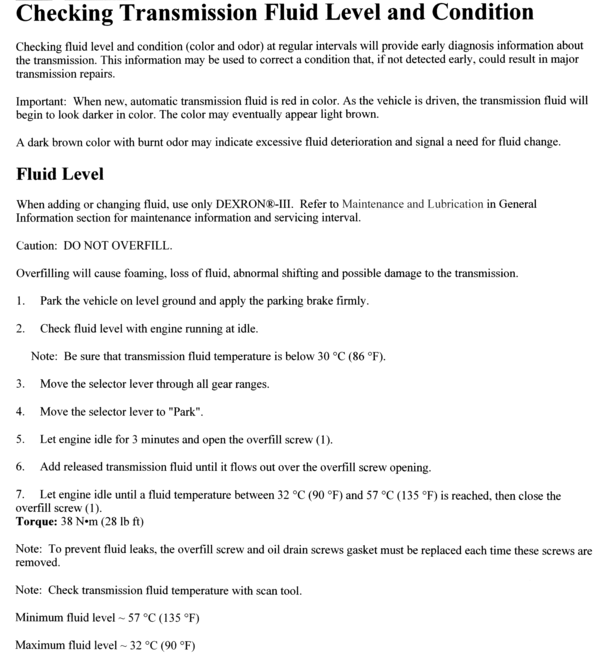

I also wanted to check the level of it and if it's low to add some but since there is no dipstick - how can I check the level or the color of it to see if it's still good? Do I need to drain it just to see if the color is still bright red or brown? or do I need to try to add some to see if it overflows every time I want to check the level because otherwise I have no idea how to tell if the level is bellow of what it should be or not.

Reply With Quote

Reply With Quote