Greetings!

I have access to a complete industrial fabrication shop with an experienced crew that are able to make whatever I need. I asked yesterday if they could help out with a bracket for my Direct TV dish install. I picked it up today, and was more than impressed with the massive result, as designed:

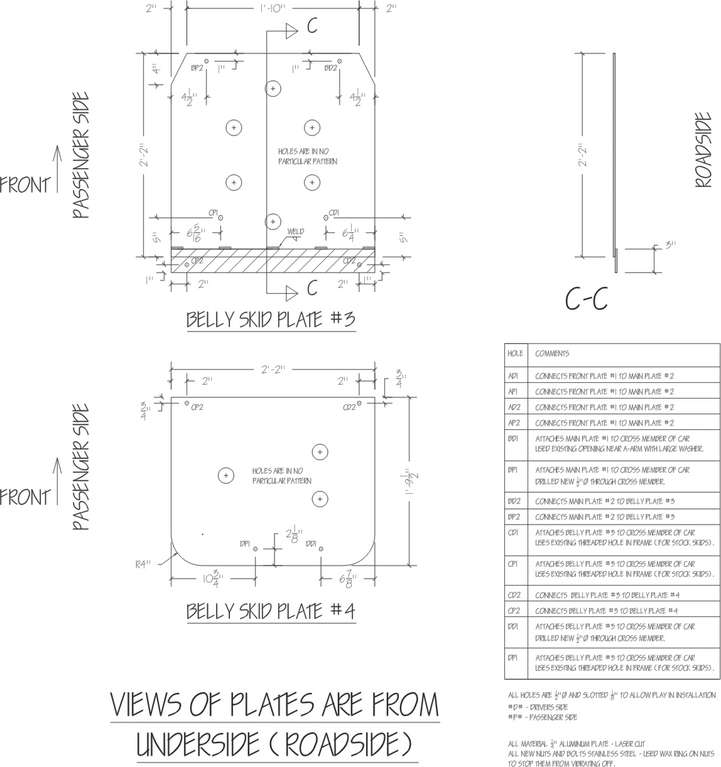

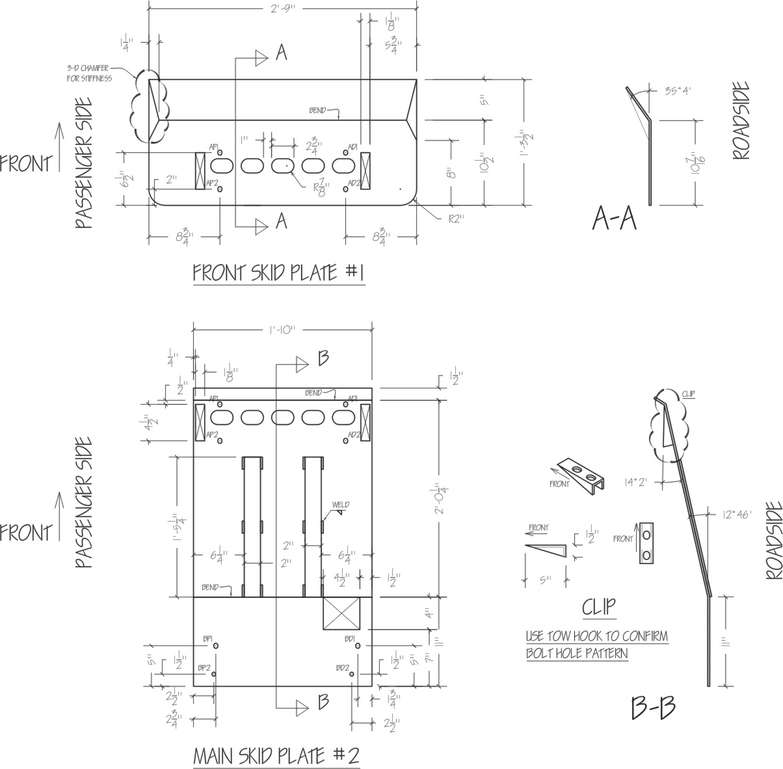

It got me thinking these guys would have no problem with some simple skid plates, say fabbed from dimond plate

Does anyone here have a pattern for front, tranny and gas skids?

I guess I should go buy 'em a couple 6 packs before I ask for another favor...

James

Reply With Quote

Reply With Quote

.

.

Bart

Bart