I installed the Magnetbra this evening.

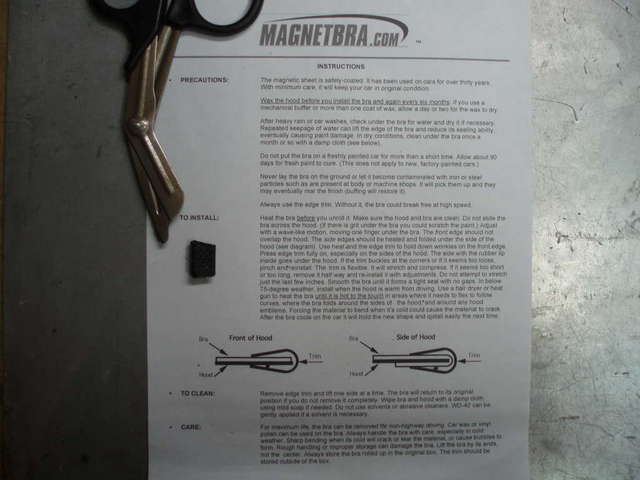

There were a few small production blemishes, one outside and a glob of the underside rubbery stuff on the vehicle side. I “fed” the trim instead of stretching it and made tight corners by heating up the trim well.

Both edging trim ends were an uneven rough cut and required pruning. I used a “penny-cutter” pair of scissors to slice through the trim with its metal strips, then dabbed flat black paint on the ends to mask where the steel strips showed on the cut edges.

You have a choice at the ends, to flush with the end of the bra, with top point of the edge trim sticking out further than the bra, or backing off a few millimeters so the top point of the edge trim is flush with the edge of the bra. I chose the latter.

The key is heat. Have a sterile flat area to heat the bra before introduction to the vehicle; run the vehicle so that the hood is warm; clean and wax while warm; prop the hood up with a block of wood, etc.

I will not leave it on for long, just for a few upcoming trips and to form the bra and trim. The creases created when you make hard corners are obvious moisture receptacles. I think if I leave the bra on for a washing or after a rain, I’ll blow those creases out with the air compressor. Thanks for the tips and I’m very pleased with the result.

Reply With Quote

Reply With Quote